Water-based Inks for screen printing on paper, board, plastics, glass, wood and other substrates

PERMAPRINT® Premium – Air-Dry Water-Based Inks

PERMAPRINT® Premium Inks are revolutionary eco-friendly, air-dry water-based inks with superior performance and colour brightness, that eliminate the use of organic solvents and are safer for the environment and the printer.

They are low odour and do not contain ozone-depleting chemicals such as CFCs and HCFCs, aromatic hydrocarbons, volatile organic solvents, phthalates, lead or other heavy metals.

Broad application

PERMAPRINT Premium inks can be used in a broad range of applications on a wide range of substrates. Common applications include printing posters and art reproduction, wallpaper, packaging, book covers, stationery and business cards, wrapping paper and slip mats through to skateboards and stickers.

PERMAPRINT Premium Inks have lower viscosity than PERMASET fabric printing inks, more similar to that of shampoo, so a finer screen mesh will typically be required. As with most water-based inks, the image area should be flooded between prints to prevent the ink from drying in.

PERMAPRINT Premium Inks do not require heat curing. They can be air dried, or may be jet dried at maximum airflow.

PERMAPRINT Premium Inks have a satin finish, are intermixable and light-fast with non-bleeding colours.

PERMAPRINT Premium Inks can be printed on sealed paper, board, Tyvek®, polyesters (Mylar®), polycarbonates (Lexan®), PMMA (Plexiglass®/Perspex®), Corflute®/Coroplast®, polystyrene and some coated metals. Printers have also enjoyed success with these inks on leather, wood and cork.

Care should be taken with some vinyls as plasticizer migration may soften the ink over time. Care should also be taken with some uncoated papers as cockling may occur.

PERMAPRINT Premium inks are designed for screen printing high lay-down hand-printed wallpaper, art reproductions, posters, packaging, notebooks and book covers, stationery, business cards, wrapping paper, placemats, cork mats, coasters and slip mats through to skateboards, stickers and backlit displays. Spectacular effects have be achieved printing on metallised Mylar® as a high end wall paper substrate.

Information on Drying, Thinning, Wash Up, Mesh Ranges, Stencil Types, Coverage and Ancillary Products are available in the PERMAPRINT Premium Colour Card and PERMAPRINT Premium Technical Data Sheet.

PERMAPRINT® Premium range

-

PERMAPRINT® Premium AQUATONE® Extender

-

PERMAPRINT® Premium AQUATONE® ColoursPERMAPRINT® Premium AQUATONE® inks are 100% solvent free, environmentally friendly inks for screen printing paper, board, wood, plastics, glass and some coated metals. For dark grounds, it is advisable to use Opaque White as an underbase. PERMAPRINT® Premium water-based inks are known for their high pigment loading, excellent coverage and intense colour. The AQUATONE® range is made up of 9 Colour Bases plus Black, a mixing White and Extender.

-

PERMAPRINT® Premium Metallic Colours

-

PERMAPRINT® Premium Process Colours

-

PERMAPRINT® Premium Glow Colours

-

PERMAPRINT® Premium Clear Gloss Varnish

-

PERMAPRINT® Premium Matting Agent

-

PERMAPRINT® Premium Opaque White

Frequently Asked Questions

We recommend a mesh range of 61-120 T (155-305 tpi) for AQUATONE, Gloss Varnish, Glow and CMYK Process Colours and 43-90 T (110-255 tpi) for the Pearl Colours, Opaque White and Matting Agent

When printing with AQUATONE Inks, it is essential to flood the image area between print strokes, immediately after lifting the screen. Small deposits or thin films of ink retained in fine mesh are prone to dry in quickly.

By flooding straight away, fresh ink will wet out these deposits and prevent drying-in.

- Ensure screen is hydrated before starting the print run.

- Ensure a nice even flood between prints, around 1-2 mm thick

- Ensure humidity is greater than 40-50% RH in the print room

- Sometimes a slightly lower mesh count can help. Maybe drop to a 77 T (195 tpi), although this should be balanced with the propensity of low viscosity ink to run through a coarser mesh.

- PERMAPRINT Premium Opaque White has much higher pigment concentration and from this, much higher opacity. It is designed for printing on dark substrates. PERMAPRINT Premium Aquatone White is almost transparent and for exclusive use in the colour mixing system.

- All products in the PERMAPRINT Premium range are designed for use on paper and other rigid substrates. These inks should not be used on textiles as they have a much stiffer handle and very little wash or dry clean resistance.

PERMAPRINT Premium Ink is the only range in the PERMASET stable that is suitable for printing on vinyl and has been used successfully for many years in a variety of applications from high end wallpapers to stickers. Care should be taken with some vinyls as plasticiser migration may soften the ink over time. The migrated plasticiser can rewet the ink, leading to compromised rub resistance. Particularly in high abrasion applications such as shoes and handbags. Such compromised rub resistance can prove problematic and thus PERMAPRINT Premium may not provide an adequate long term result when printed on some vinyls. Test first.

Given the high solids in PERMAPRINT Premium and consequent low free water content, there may be issues with closing in on finer meshes. Fine meshes and large particle size also work against high print opacity. So, particularly for the PERMAPRINT Premium Pearl Gold, you may need to double pump the print. The other colours seem to perform better than the Gold, opacity wise, but it is expected that all Pearls would benefit from double or more print strokes.

AQUATONE® Inks have lower viscosity than PERMASET fabric printing inks, more similar to that of shampoo, so a finer screen mesh will typically be required. As with most water-based inks, the image area should be flooded between prints to prevent the ink from drying in.

PERMAPRINT Premium Inks have relatively high solids and proportionally little free water. In common with HSA textile inks, they are more prone to drying in on the screen.

When printing with water-based inks, it is good practice to flood the image area between print strokes, immediately after lifting the screen. Small deposits or thin films of ink retained in fine mesh are prone to dry in quickly.

By flooding straight away, fresh ink will wet out these deposits and prevent drying-in.

- Ensure screen is hydrated before starting the print run.

- Ensure a nice even flood between prints, around 1-2 mm thick

- Ensure humidity is greater than 40-50% RH in the print room

- Sometimes a slightly lower mesh count can help. Maybe drop to a 77 T (195 tpi), although this should be balanced with the propensity of low viscosity ink to run through a coarser mesh.

Find more PERMASET FAQs here

Get more from your PERMAPRINT Premium Ink

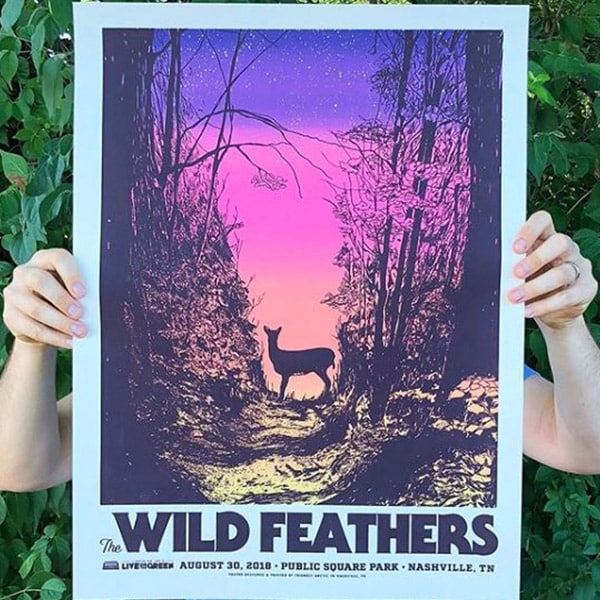

Inspiration

Hear from designers and screen printers who print posters, notebooks and homewares using PERMAPRINT Premium Inks

Buy PERMAPRINT Premium Ink online

Buy PERMAPRINT Premium Inks online and have them delivered to your door