Why choose water-based inks?

In today’s world, where sustainability is a top priority, screen printing inks for trade printers play a crucial role in promoting more environmentally friendly printing practices. By choosing PERMASET water-based inks, your business can take a significant step towards becoming more eco-friendly while also attracting more customers, producing softer, crisper prints and making your print room safer for your employees and your finished garments safer for your customers.

Low cure temperature capability

Looking for printing inks for Trade Printers with products that are eco-friendly but also capable of low temperature cure? PERMASET Inks offer just that, making them a top choice for printing on heat-sensitive fabrics and ensuring the highest quality results.

The versatility of PERMASET Inks allows appropriate cure on heat sensitive fabrics without needing a cocktail of highly reactive low-cure additives, so they’re safer for your staff and safe on the final garment.

For printing on extremely heat sensitive substrates such as nylon and polypropylene tote bags, look no further than PERMAPRINT Hybrid Ink. These are air dry inks that exhibit a rare combination of flexibility and rub resistance, all in an air dry ink. Whilst designed for air-dry, production can be accelerated by passing finished items under a jet drier at low heat and maximum air flow. Care needs to be exercised to ensure that items do not block when stacked whilst still warm or partially dried.

Improved printability

PERMASET Inks are designed with improved printability in mind, providing excellent coverage, smooth texture, and effortless application, making them the ideal choice for professional printers.

PERMASET SUPERCOVER in particular requires far less effort to print than a comparable plastisol Opaque White for example. This translates to less wear and tear on the squeegee, on the mesh, on the stencil and if you’re printing manually, then on the joints of the printer. So really, it’s less wear all round and, in the best possible way, an example of treading lightly on the planet.

Sustainability comes first

By using water-based and eco-friendly materials, PERMASET Inks set themselves apart as one of the world’s leading screen ink manufacturers for trade printers. PERMASET Inks significantly reduce their environmental impact, making them a sustainable choice for printing on textiles.

Not only are PERMASET Inks water-based, non-toxic, and free of harmful chemicals, but they also have lower energy consumption during production and reduced water usage.

High-quality inks

Whether you’re an experienced print practitioner or just starting out, PERMASET Inks are sure to help you take your designs to the next level. With a unique formulation and high pigmentation, PERMASET screen printing inks produce stunning, vivid colours that stand out on any fabric, from cotton to silk, hemp and many synthetics, without the need for additives. Plus our PERMAPRINT Premium Inks for printing posters and art reproduction, wallpaper, packaging, book covers, stationery, wrapping paper and slip mats through to skateboards and stickers, have the same eco-friendly credentials – allowing you to sustainably print other types of merchandise on substrates other than fabric.

No harmful chemicals

Unlike traditional inks that are packed with harmful chemicals, PERMASET Inks are made with a water-based, non-toxic formula that is free from dangerous chemicals. This makes them safe to use and handle, reducing the risk of harmful exposure for both you, your staff, your customers and for the environment.

Valuing people and our communities

PERMASET is committed to supporting local communities, using ethically sourced materials and supporting small businesses to help create a more sustainable future. By choosing PERMASET Ink, you can feel good knowing that you’re supporting a company that values people and communities as much as they value the environment and the quality of their products.

Free download: Moving to water-based inks

Eco-friendly Screen Printing: The Top 6 Benefits of Water-based Inks

For decades, plastisol inks were the go-to ink for most printers. They were easier to use compared to water-based inks and more forgiving with regard to housekeeping, but there was a massive ecological downside that was mostly ignored… until now.

Water-based inks have improved, both in terms of quality and ease of use. Many professional printers have switched to printing with water-based inks and indeed prefer them due to their exceptionally soft handle, the fact that they are safe to use and their environmentally friendly credentials that many customers now demand.

Tips and tricks when moving from plastisol inks to water-based inks

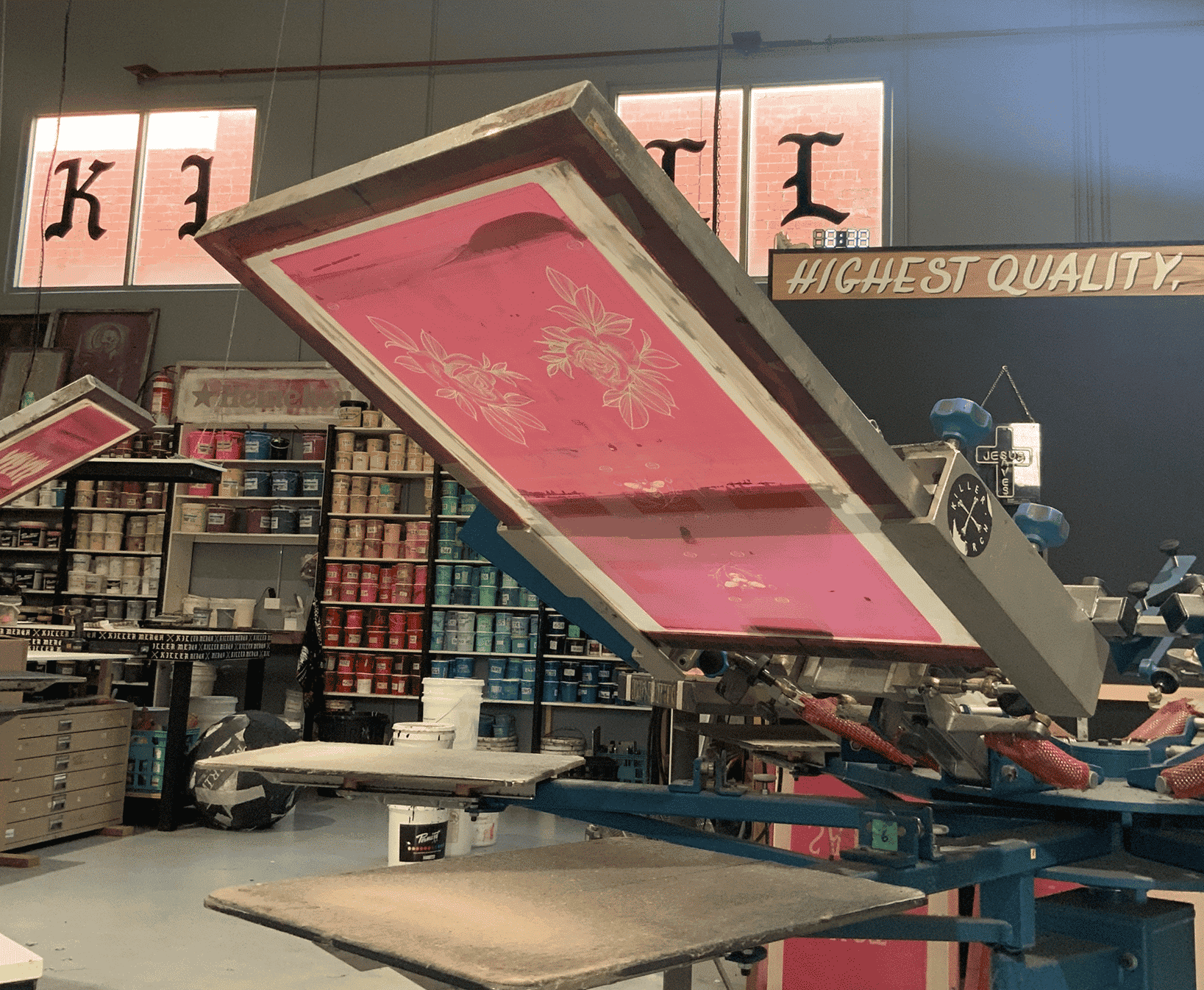

@idressmyselfprint

@idressmyselfprint

Hear how I Dress Myself print shop has used water-based inks in their ethical business

Hear how I Dress Myself print shop has used water-based inks in their ethical business

Learn about our sustainable inks

PERMASET AQUA

Setting the industry standard of water-based inks for light-coloured fabrics

PERMASET SUPERCOVER

Unsurpassed colour and opacity even on the darkest fabrics

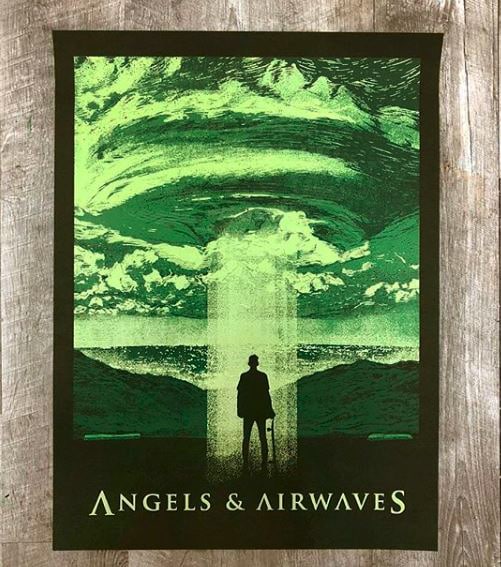

PERMAPRINT PREMIUM

Inks for printing on paper, board, plastic, glass, wood, metal & other substrates

PERMATONE

Colour matching set for printing on fabrics, can be mixed to match 1869 colours. Organically Approved by the Soil Association of the UK to GOTS v 6.0

AQUATONE

Colour-matching set of inks for printing on paper, board, plastic, glass, wood, metal & other substrates

Frequently asked questions

Absolutely! Water-based inks can be used in automated screen printing machines, and many printers actually prefer using water-based inks in their automated printing processes. Some of the advantages of using water-based inks in automated printing include their fast drying times, ability to produce sharp and crisp designs, and their ease of use with automatic machinery.

The cost of screen printing ink can vary depending on factors such as the brand, colour, and quantity/pack size purchased.

Whilst even in the recent past, the plastisol lobby was happy to characterise water-based inks as being more expensive, the reality is that the cost of water-based inks vs solvent-based inks and plastisols has decreased to the point that in most cases, water-based inks are less expensive than solvent-based inks.

This difference becomes even more pronounced when you factor in the savings associated with using a more environmentally friendly product against the increasing disposal costs of solvent based wastes.

When comparing water-based inks costs to plastisols, water-based inks are often less expensive, in part because they do not require the same chemical additives as plastisol inks. These additives, and indeed the base raw materials themselves, are increasingly subject to cost increases as the damage that had always been caused during their manufacture, processing and disposal are being marked to market and the real cost of environmental abuse increasingly being reflected in increased costs associated with insurance claims and law suits.

So, while the price of ink can vary based on brand and specific ink type, it’s definitely worth considering water-based inks as a cost-effective and eco-friendly option for your print shop.

Proper storage and handling is important to ensure the best performance and longevity of water-based inks.

First, it’s important to store water-based inks in a cool, dry place, out of direct sunlight and away from sources of heat. It’s also important to keep the ink containers tightly sealed when not in use to prevent drying out by evaporation and contamination from the ingress of pathogens…..the flipside of having an eco-friendly product.

When handling any ink product, it’s recommended to wear gloves to prevent direct contact with the skin, especially for prolonged periods. Additionally, it’s important to avoid cross-contamination by using separate spatulas and containers for different ink colours.

Thorough cleaning of spatulas and other equipment after use is also critical to prevent any cross contamination. The use of hot water and appropriate hygiene measures will also go a long way to ensure minimum wastage through biological contamination.

Yes, inks within each range can be mixed.

As one of the top printing inks for trade printing, Inks from the various PERMASET ranges can provide a wide range of high-quality and versatile inks that can be mixed within the same range.

However, when mixing between ranges, e.g. PERMASET SUPERCOVER® opaque inks with PERMASET AQUA® transparent inks, it is important to exercise caution.

First, the opacity of the print will be reduced compared, for example, to a print with PERMASET SUPERCOVER® ink alone. This will be particularly noticeable in prints over dark backgrounds.

Second, some combinations exhibit slight to significant incompatibility. As above, exercise caution and test first before embarking on a production run.

When mixing water-based inks, it’s important to use clean mixing containers and imperative to mix the inks thoroughly to ensure the new colour is consistent throughout the mixture; thus transparent or semi-transparent containers are recommended.

Finally, it is recommended that the mix formula, operator details (initials) and date are all recorded on the outside of the container and that the lid be tightly sealed after use.

Note: you should not mix PERMASET fabric inks with PERMAPRINT Premium Inks for printing paper and other substrates as they are different formulations for different applications.

PERMASET Inks are 100% water-based and do not contain any organic (hydrocarbon) solvents. The only solvent is water.

There are a number of white inks in the PERMASET range. Which is the correct white ink to use as an underbase for overprinting with PERMASET standard and PERMATONE inks when printing on dark fabrics?

PERMASET FIRST DOWN WHITE Ink has been specifically formulated for use as an underbase (flash white). It is used by trade printers who wish to print on dark fabrics but use regular PERMASET Standard colours or PERMATONE Inks to retain their superior softness and vibrancy. The First Down White should only be used by shops with multi-station print facilities where tight registration can be maintained.

PERMASET SUPERCOVER WHITE is the premium opaque white ink for printing directly onto dark fabrics. It has the highest levels of titanium dioxide pigment for use on dark coloured fabrics. Excellent opacity in a water-based ink. Despite having been the flagship product in the PERMASET SUPERCOVER range for well over 30 years, in more recent times, this style of ink has become popularly known as HSA or High Solids Acrylic.

PERMASET STANDARD WHITE is a soft handle white ink for printing onto light coloured fabrics. It delivers a significantly softer hand than the PERMASET SUPERCOVER White ink, yet still delivers a beautifully crisp white print and looks spectacular when used for white-on-white prints.

My inks are drying into the screens. Help!

This is probably the biggest problem for people who are starting to use or are changing over to water-based inks, particularly from plastisols, which are very forgiving in this regard.

Prevention is better than cure, so a good first step is to keep humidity in the print area above 40-50% RH. Once the relative humidity gets below 40%, the inks will show much greater propensity to dry in and printing will become a lot more difficult. Getting an hygrometer for your print room is a great investment.

When people first start printing with water based inks, they can use a fine mist of water every 15-20 prints to maintain the moisture of the ink on the screen. Many people swear by this method. The most important thing is to flood the screen with a layer of ink (1-2 mm; 1/16-1/10”) and to keep the ink moving; that is, work quickly (but don’t rush). If a screen has been sitting around doing nothing for a while, pull a test print from it onto a scrap T-shirt, piece of fabric or even newsprint and inspect the clarity of the print, particularly around any fine detail.

If the ink does start to dry on the screen a little, don’t panic. Just pull another print on a test piece, so that as much ink is cleared from the image area of the mesh as possible, take a damp rag and clean both sides of the screen, then remove excess moisture with another rag. Reflood the screen, take another test print and then you’re good to go again.

Mesh count is often a factor. Most garment printers use a 43T (110 tpi) mesh. All other things being equal, the higher the mesh count, the quicker the ink will dry in. However, S-meshes have been a wonderful invention for printing with water based inks. With S-meshes, higher mesh counts can be more forgiving than the same thread count with a conventional mesh. Check out the S-mesh comparison tables.

Use a good emulsion that is compatible with water-based inks and maintains its integrity and you can get good results even with a coarser mesh. With increased experience, you will eventually master 77-90T (195-225 tpi) meshes for SUPERCOVER and up to 120 T (305 tpi) for PERMASET AQUA, PERMATONE and PERMAPRINT Premium.

This is probably the biggest problem for people who are changing over to water-based inks, particularly from plastisols, which are very forgiving in this regard.

Prevention is better than cure, so a good first step is to keep humidity in the print area above 40-50% RH. Once the relative humidity gets below 40%, the inks will show much greater propensity to dry in and printing will become a lot more difficult. Getting an hygrometer for your print room is a great investment.

When printers first start using water based inks, they can spray a fine mist of water every 15-20 prints to maintain the moisture of the ink on the screen. Some printers swear by this method. The most important thing is to flood the screen with a layer of ink (1-2 mm; 1/16-1/10”) and to keep the ink moving; that is, work quickly (but don’t rush). If a screen has been sitting around doing nothing for a while, pull a test print from it onto a scrap T-shirt, piece of fabric or even newsprint and inspect the clarity of the print, particularly around any fine detail.

If the ink does start to dry on the screen a little, don’t panic. Just pull another print on a test piece, so that as much ink is cleared from the image area of the mesh as possible, take a damp rag and clean both sides of the screen, then remove excess moisture with another rag. Reflood the screen, take another test print and then you’re good to go again.

Mesh count is often a factor. Most garment printers use a 43T (110 tpi) mesh. All other things being equal, the higher the mesh count, the quicker the ink will dry in. However, S-meshes have been a wonderful invention for printing with water based inks. With S-meshes, higher mesh counts can be more forgiving than the same thread count with a conventional mesh. Check out the S-mesh comparison tables.

Use a good emulsion that is compatible with water-based inks and maintains its integrity and you can get good results even with a coarser mesh. With increased experience, you will eventually master 77-90T (195-225 tpi) meshes for SUPERCOVER and up to 120 T (305 tpi) for PERMASET AQUA, PERMATONE and PERMAPRINT Premium.

We have your back

Our help centre is regularly updated with instruction videos, how-tos, colour cards, technical data sheets and advice to assist you on your screen printing journey