Since the late 1980s, plastisol ink had become the go-to ink for most textile printers. Plastisols were seen as easier to use compared to water-based ink since they seemed to require fewer steps and were also widely seen as easier to work with.

But that was then.

Not only have water-based inks improved dramatically over the years in quality and ease of use, but the world at large is now more conscious of the previously unacknowledged environmental costs of using plastisols.

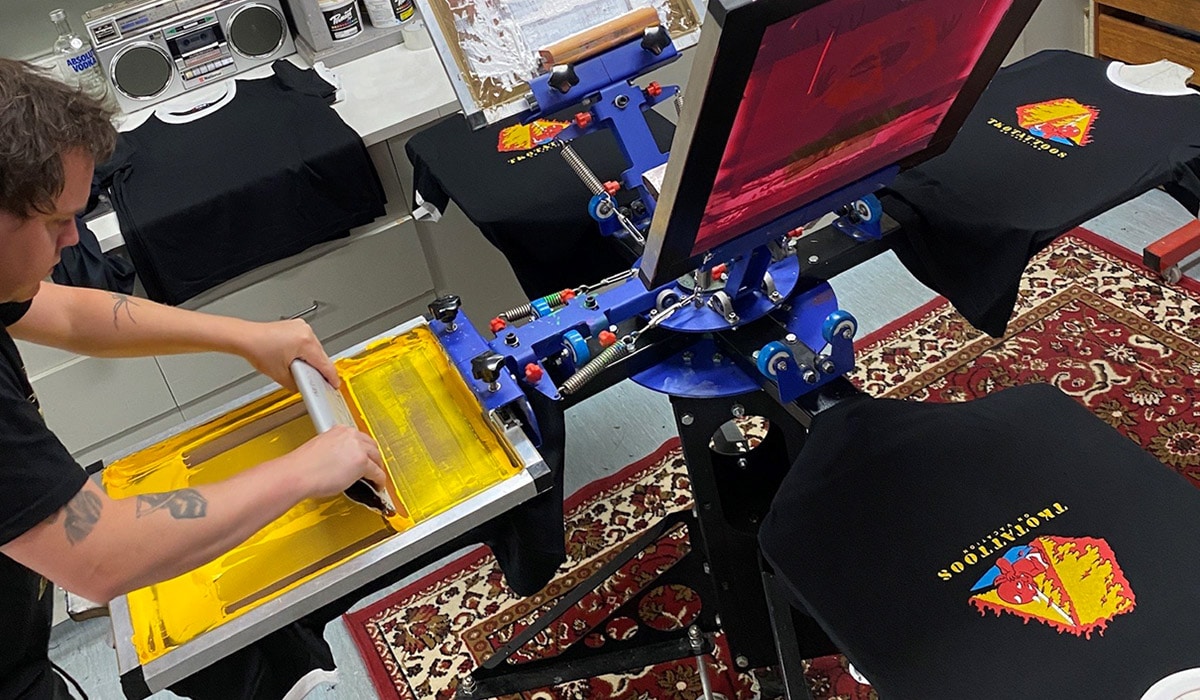

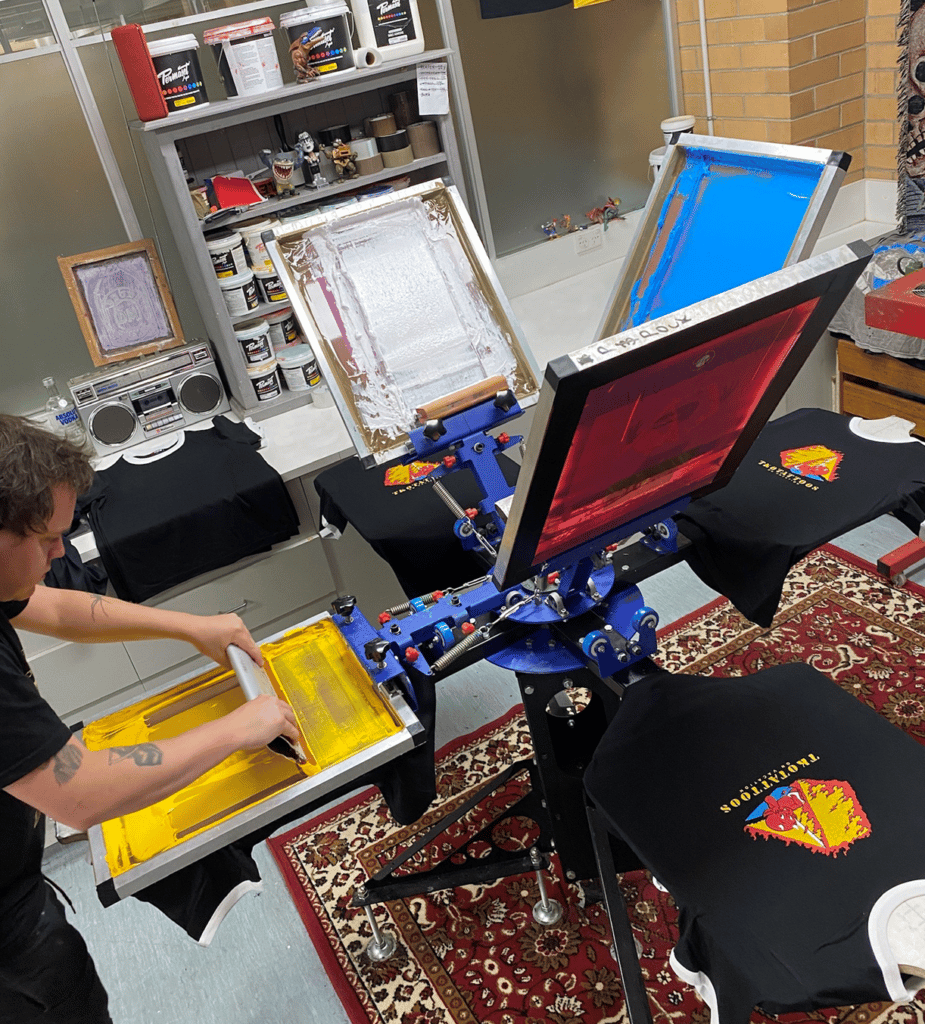

Today, many print professionals have already switched or are switching to water-based inks for screen printing textiles. This change has been driven by a preference for soft handle, the fact that they are safe to use and their enviro-friendly credentials.

This is no fad. Water-based inks have greatly improved over the last 30 years, such that many printers now consider them the superior ink. Why superior? Here are the top six reasons…

1. Eco-friendly ink

In the current market, this is probably seen as water-based inks’ greatest strength. In a world where protecting the environment has become a top priority, water-based inks allow printers to do their part. Plastisol inks are not eco-friendly at all, being based on PVC resin and phthalate plasticizer and typically cleaned up with petrochemical solvents. By contrast, PERMASET water-based Inks are completely free from PVC and phthalates and are also free of harmful ozone depleting chemicals and aromatic hydrocarbons. Now that’s what you call eco-friendly!

2. Prints with soft hand

Unlike most plastisol inks, water-based inks produce a soft hand. The technology of PERMASET water-based ink ensures good adhesion with the print sitting lightly on the fibre and this in turn allows the fabric to retain its natural softness. These factors combine to give your prints unparalleled softness and flexibility.

Plastisol technology, on the other hand, is the same as traffic cones and clear table coverings in cheap restaurants; not soft and not comfortable. Plastisol inks work on apparel by penetrating the fabric, restricting its flexibility and compromising comfort. Plastisol prints also exude plasticizer (the oily feel on top of and behind a plastisol print), while the continued leaching of plasticizer long after the first wash makes them a biological hazard.

Garments and homewares printed with water-based inks are much more comfortable for the wearer and safer for use against delicate skin.

3. Higher quality prints

Water-based inks produce longer lasting prints with impeccable detail, with more defined, sharper edges. This includes half-tones and other detailed designs, making them the perfect choice for printing intricate, detailed designs. Because water-based inks are intrinsically soft, these prints will also become softer over time as opposed to progressively harder like plastisol prints do.

4. Better for your health

Because they are free from harmful chemicals, water-based inks are safe, not just for the environment but for the printer as well. Water-based inks wash up in water. There are no harsh chemicals, volatile organic solvents in the inks or VCM (Vinyl Chloride Monomer given off during the plastisol curing process) that printers are exposed to as an inhalation risk.

5. Easier clean up

Water-based inks clean up easily after printing with just water, rather than the petrochemical solvents required to clean plastisol screens and equipment. No harmful chemicals, just water.

6. More business

Regulation in many jurisdictions has already banned or heavily restricted the use of many, if not all, phthalates on infant garments. So, if you’re looking to offer these printed items, then you’ll have to go phthalate free or use water-based inks.

Using water-based inks won’t just increase your business opportunities by allowing you to expand into the children’s wear market. Many customers now prefer and indeed are specifying water-based prints. By using water-based inks, you will be able to offer prints that are softer and breathe better compared to plastisol prints.

Plastisol prints feel heavy on top and sweaty underneath.

With water-based inks, there is no chance of plasticizer leaching from the print into your skin. The quality of the print is outstanding and best of all, it’s environment friendly, something that more and more consumers are demanding.

Using water-based inks has never been easier or more advantageous. If you haven’t already done so, you may want to switch as soon as possible. A great place to start is by getting hold of some PERMASET inks.

Find your closest PERMASET Stockist here or buy PERMASET Inks Online here. Alternatively, visit the PERMASET product page for further information.

COPYRIGHT© Colormaker Industries 2022.

Subscribe to get the latest inspiration, news & advice direct to your inbox

More articles

@imearthie

@imearthie

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand