During the late 1980s and early 1990s, plastisol ink became the ink of choice for most textile printers. Plastisols were “easier to use” compared to water-based ink since they seemed to require fewer steps and were a lot more forgiving of poor screen prep.

But that was then.

Not only have water-based inks improved dramatically in quality and ease of use, but the world at large is now more conscious of the hidden environmental costs of using plastisols.

Many print professionals have already switched to water-based inks for screen printing textiles. This change has been driven by a preference for soft handle, the fact that they are safe to use, their enviro-friendly credentials and increased business arising from demand for Organic printing.

Using water-based inks is getting easier. If you haven’t already done so, you may want to make the switch. For further information read our PERMASET Blog 6 Good Reasons to Change to Water-based Ink.

Browse our store and purchase

PERMASET Inks & accessories online

Projects, tips & ideas to keep you inspired

@imbueddesign

@imbueddesign

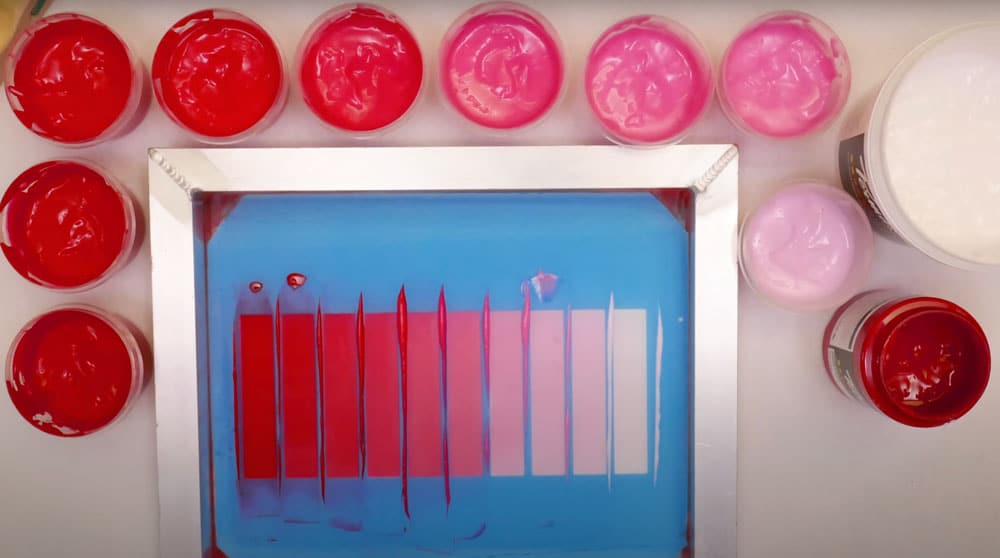

Learn from designer Imbued Design how to make PERMASET reductions using Print Paste

Learn from designer Imbued Design how to make PERMASET reductions using Print Paste

@kltworks

@kltworks

Hear how US designer Kristin Loffer Theiss created 2,687 colourful face masks from screen printed fabric scraps

Hear how US designer Kristin Loffer Theiss created 2,687 colourful face masks from screen printed fabric scraps

Get more from your PERMASET Ink

Help Centre

Whether you’re a beginner or a trade printing expert, we have the answers and how tos for you.

PERMASET Inks for Trade Printers

See how PERMASET Inks are used in the industry by Trade Printers.