Part 1 – REDUCTIONS: Getting to know PERMASET® Textile Screen Printing Inks

Most artists and designers begin their artistic journey by exploring the colour palette. Of particular interest is how a purchased colour is expressed as its intensity is reduced.

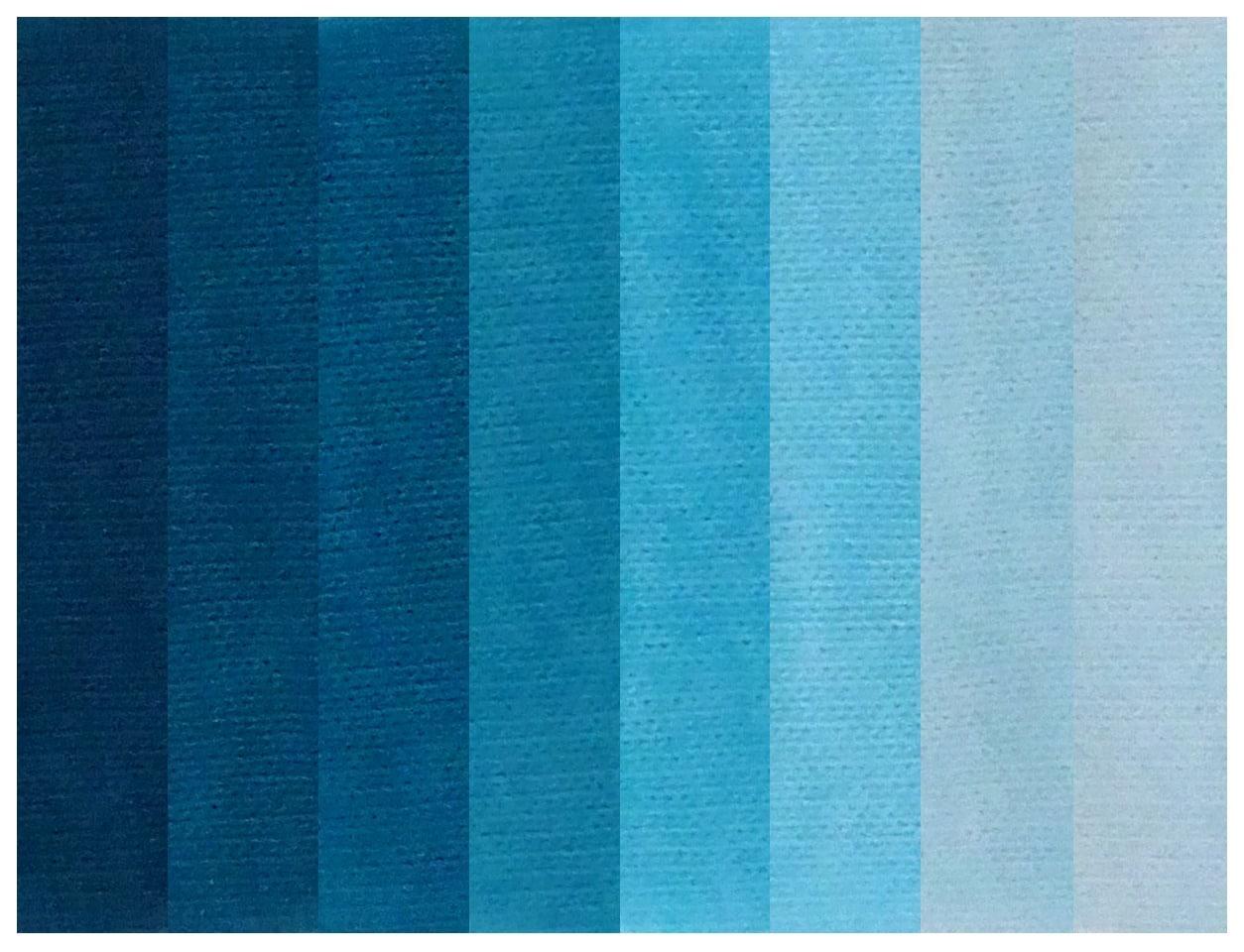

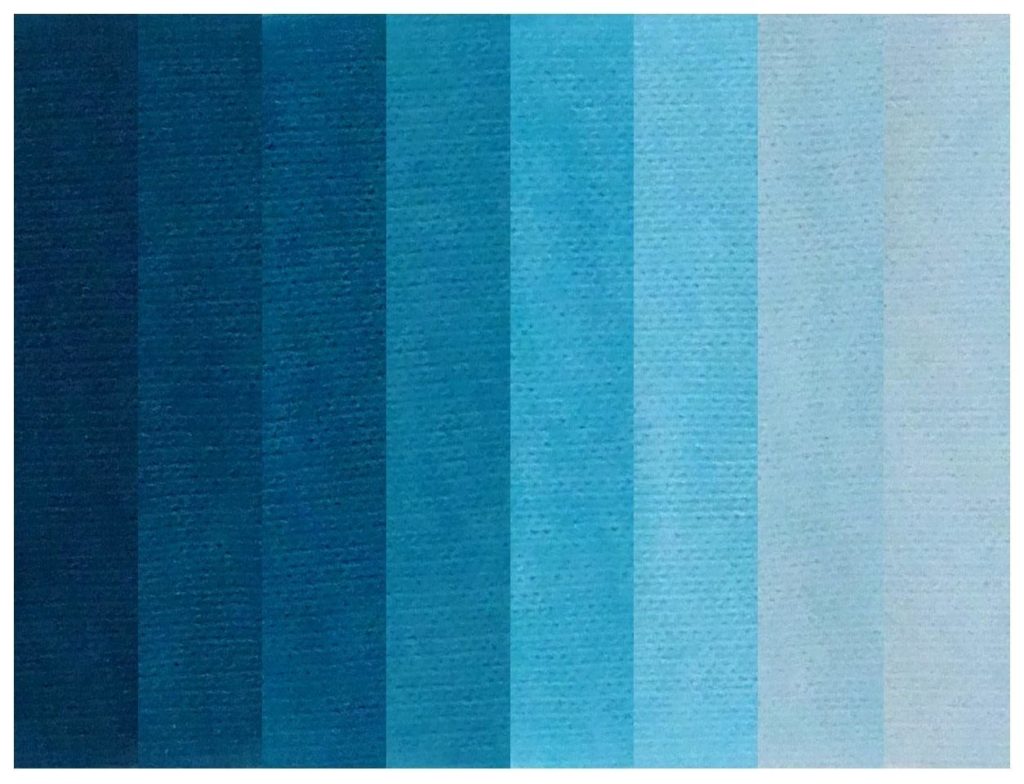

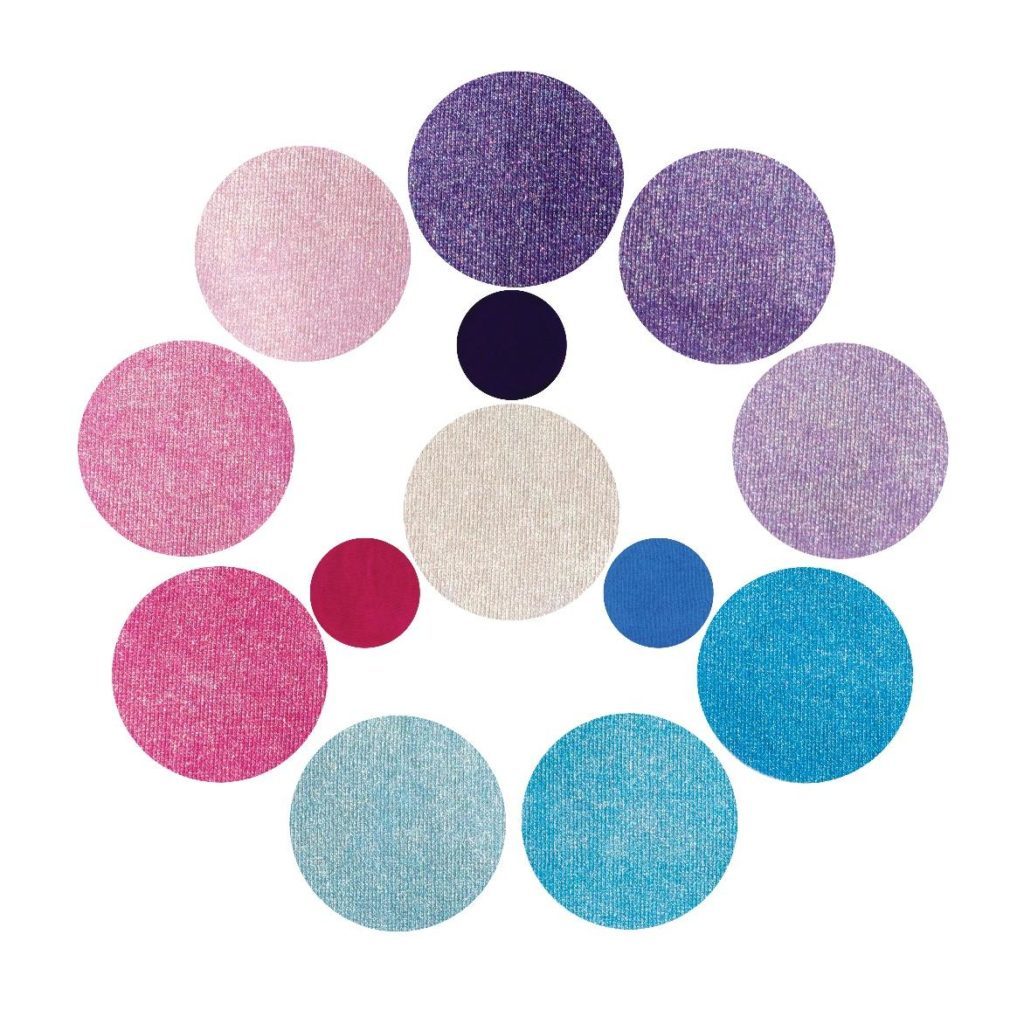

PERMASET Screen Printing Inks are highly pigmented and dilutions, or more correctly “reductions”, are achieved by mixing with PERMASET Print Paste. Adding PERMASET Print Paste to any PERMASET Ink reduces the intensity of the colour, thus producing a lighter colour called a reduction.

PERMASET AQUA Inks are transparent and reductions will appear as tints when printed on white fabric. Tints can also be achieved by mixing PERMASET Inks with PERMASET White. If your design incorporates tints, then consider the following when deciding whether to use PERMASET Print Paste or PERMASET White:

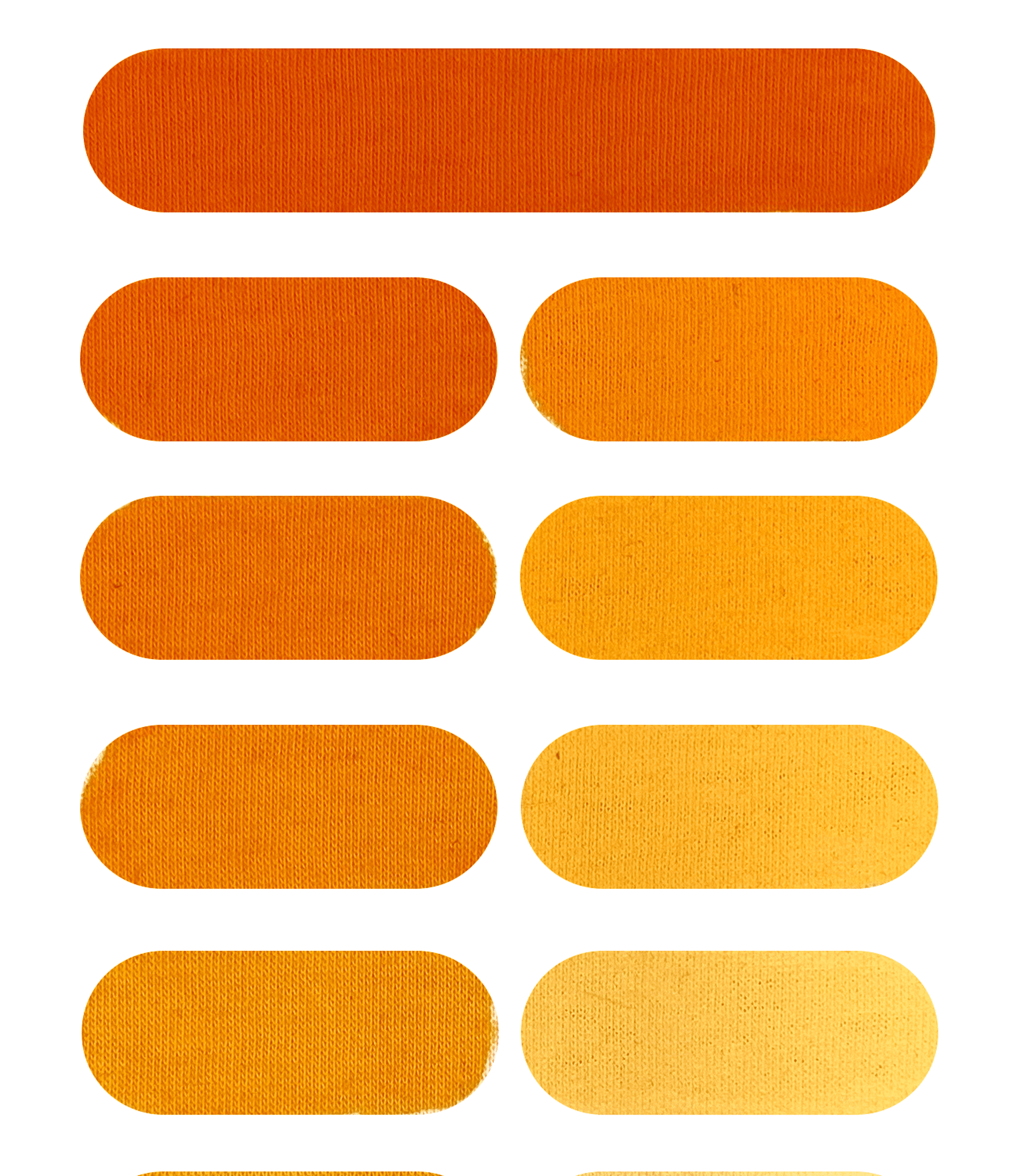

- Reductions made with Print Paste will:

- appear as tints when screen printed on white fabric,

- appear as tones when printed on grey fabrics,

- have a soft handle when dry and

- require less PERMASET Ink to make up a particular tint because the ink is dispersed into a transparent medium. Less ink used saves you money in raw materials, time and energy in the dryer, and for all these reasons, has a lighter environmental footprint.

- A reduction made with PERMASET White will:

- appear as a pastel,

- have a slightly harder handle,

- have a higher opacity so the colour of the fabric will not show through as much and

- require more PERMASET Ink to make up a particular tint because the ink is dispersed into an opaque medium. This will have a heavier environmental footprint.

PERMASET AQUA Orange R Reductions with PERMASET Print Paste (left) and PERMASET White (right) at the same concentration

The final screen printed colour is also dependent on screen mesh size, squeegee hardness and shape, number of strokes and pressure applied during the stroke. When assessing colour, it is important to make test prints and assess colour after curing.

Watch how PERMASET Bright Red is reduced with Print Paste on our YouTube channel:

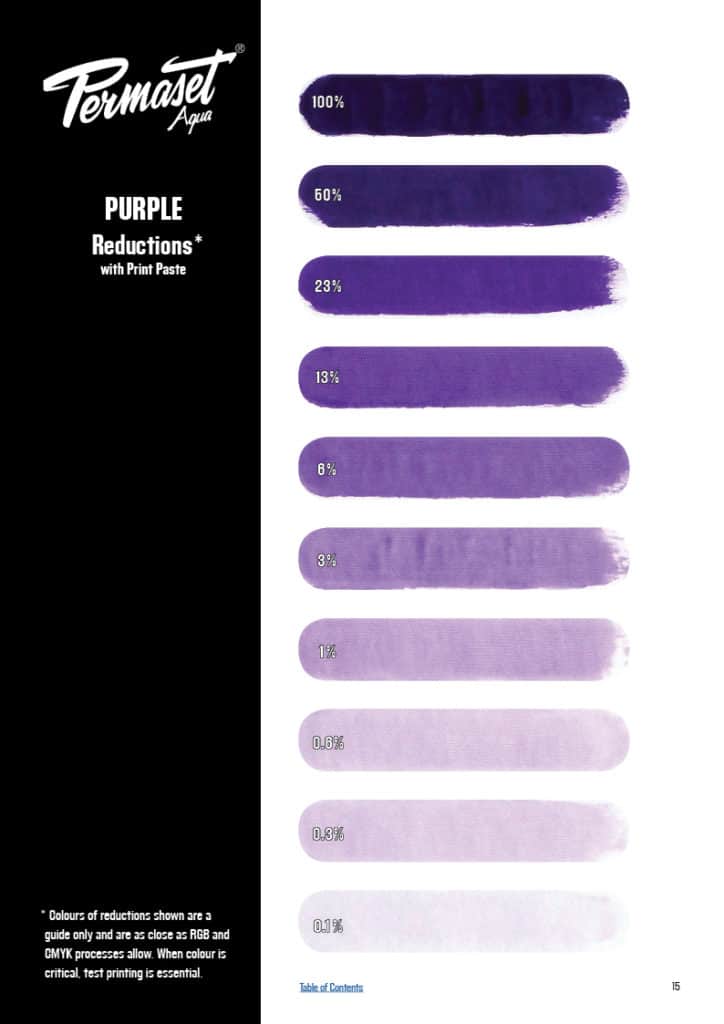

To save time, a full set of PERMASET Reductions is available as an e-BOOK that you can down load and have on hand for easy reference.

Mixing Metallic Inks

Reductions can also be made with PERMASET Pearl White too. All PERMASET Standard and Metallic Inks are intermixable. Mix PERMASET Metallic Pearl White with PERMASET Standard Colours to create a wide range of metallic colours.

Rose Gold is trending in popularity and is seen in jewellery, shoes and even hair colour! It is very easily made by mixing PERMASET Metallic Copper with Metallic Pearl White.

PERMATONE Reductions

PERMATONE® Screen Printing Inks are part of the PERMASET range and are typically used for commercial colour matching. PERMATONE inks have a high pigment values. The following image shows PERMATONE Black reductions with PERMASET Pearl White. A 50% PERMATONE Black with PERMASET Pearl White (at the red dot) reduction is still quite black as shown in the image below. A mid grey is achieved around the 5% mark (at the blue dot). Even at 0.5% PERMATONE Black with 99.5% PERMASET Pearl White the black is still quite strong (at the green dot).

TIP: When mixing a reduction always add the coloured ink to the Print Paste in small increments until you reach the desired tint.

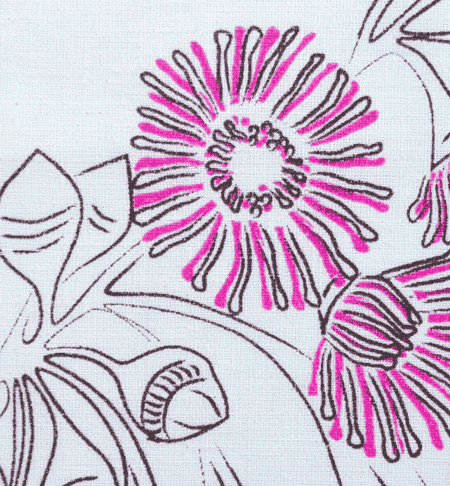

Case Study: Flowering Gums Design for Linen Tea Towels

A Margaret Preston inspired design was developed for screen printing on linen tea towels. The initial print run used 100% PERMATONE Black and 100% PERMATONE Magenta in keeping with the strong blacks and colour blocks typical of Margaret Preston’s linocuts.

The design developed had a delicate feel and suggested a softer approach to colour. A series of print runs were made each time halving the strength of PERMATONE inks in the reduction process until settling at 6% PERMATONE Magenta and 3% PERMATONE Black. At these levels, the reductions gave the desired delicate effect reminiscent of flowering gums.

PERMATONE Inks are highly intense and even at 3% Black and 6% Magenta, the reductions retained the vibrant colour of PERMATONE Inks. The PERMATONE range has been granted approval by the Soil Association in the UK, having successfully met the requirements of the Global Organic Textiles Standards (GOTS) for non-organic chemical inputs for use in organic textile processing.

In the second part of this series, we will show you how to confidently create colour harmonies using PERMASET Inks. To purchase PERMASET Print Paste, contact your local PERMASET Stockist or you can buy from our PERMASET Online Shop.

COLORMAKER INDUSTRIES© 2022.