Projects, tips & ideas to keep you inspired

Eco-friendly Screen Printing: A Guide for Artists and Printers

Eco-friendly Screen Printing: A Guide for Artists and Printers

@evebracewell

@evebracewell

Getting started on a street beautification project

Getting started on a street beautification project

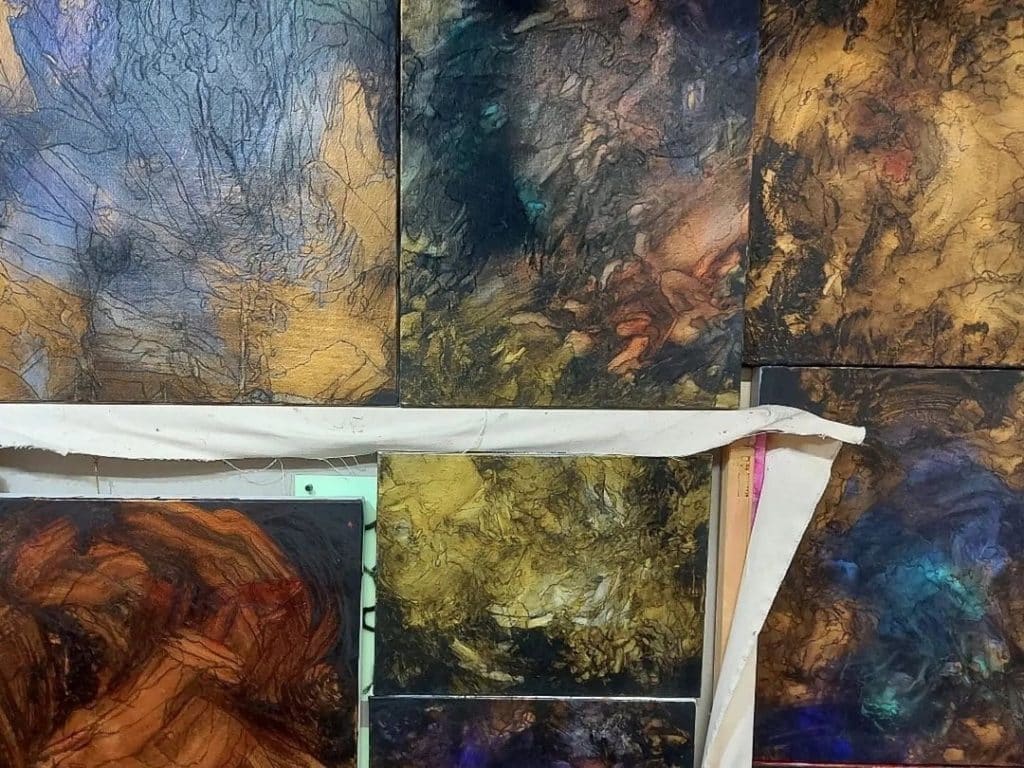

Abstract Realities Exhibition used PERMACRYLIK Paints as Part of the Artwork

Abstract Realities Exhibition used PERMACRYLIK Paints as Part of the Artwork

The handy guide to marketing your screen printing business on social media

The handy guide to marketing your screen printing business on social media

@clementia_fish_Shop

@clementia_fish_Shop

How to screen print on different kinds of fabrics

How to screen print on different kinds of fabrics

@seaurchindesign

@seaurchindesign

How to screen print your own T-shirt in 6 easy steps

How to screen print your own T-shirt in 6 easy steps

@kadevaljaart

@kadevaljaart

Artist Kade Valja Explores Energetic Forces using PERMACRYLIK Scenic Paints

Artist Kade Valja Explores Energetic Forces using PERMACRYLIK Scenic Paints

Abstract Realities Exhibition used PERMACRYLIK Paints as Part of the Artwork

Abstract Realities Exhibition used PERMACRYLIK Paints as Part of the Artwork

Creating a wall mural: Beginner scenic painting techniques explained

Creating a wall mural: Beginner scenic painting techniques explained

The handy guide to marketing your screen printing business on social media

The handy guide to marketing your screen printing business on social media

@seaurchindesign

@seaurchindesign

How to screen print your own T-shirt in 6 easy steps

How to screen print your own T-shirt in 6 easy steps

@art_of_zig

@art_of_zig

How to screen print organically: Finding supplies in 2022

How to screen print organically: Finding supplies in 2022

@creativecloudexpressjp

@creativecloudexpressjp

Check out 5 fabulous apps for designing T-shirts

Check out 5 fabulous apps for designing T-shirts

@inkandspindle_

@inkandspindle_

Are PERMASET screen print inks compostable?

Are PERMASET screen print inks compostable?

@chezwilliam_sreenprint_co

@chezwilliam_sreenprint_co

How to make custom 3D prints using PERMASET Puff Paste

How to make custom 3D prints using PERMASET Puff Paste

@imbueddesign

@imbueddesign

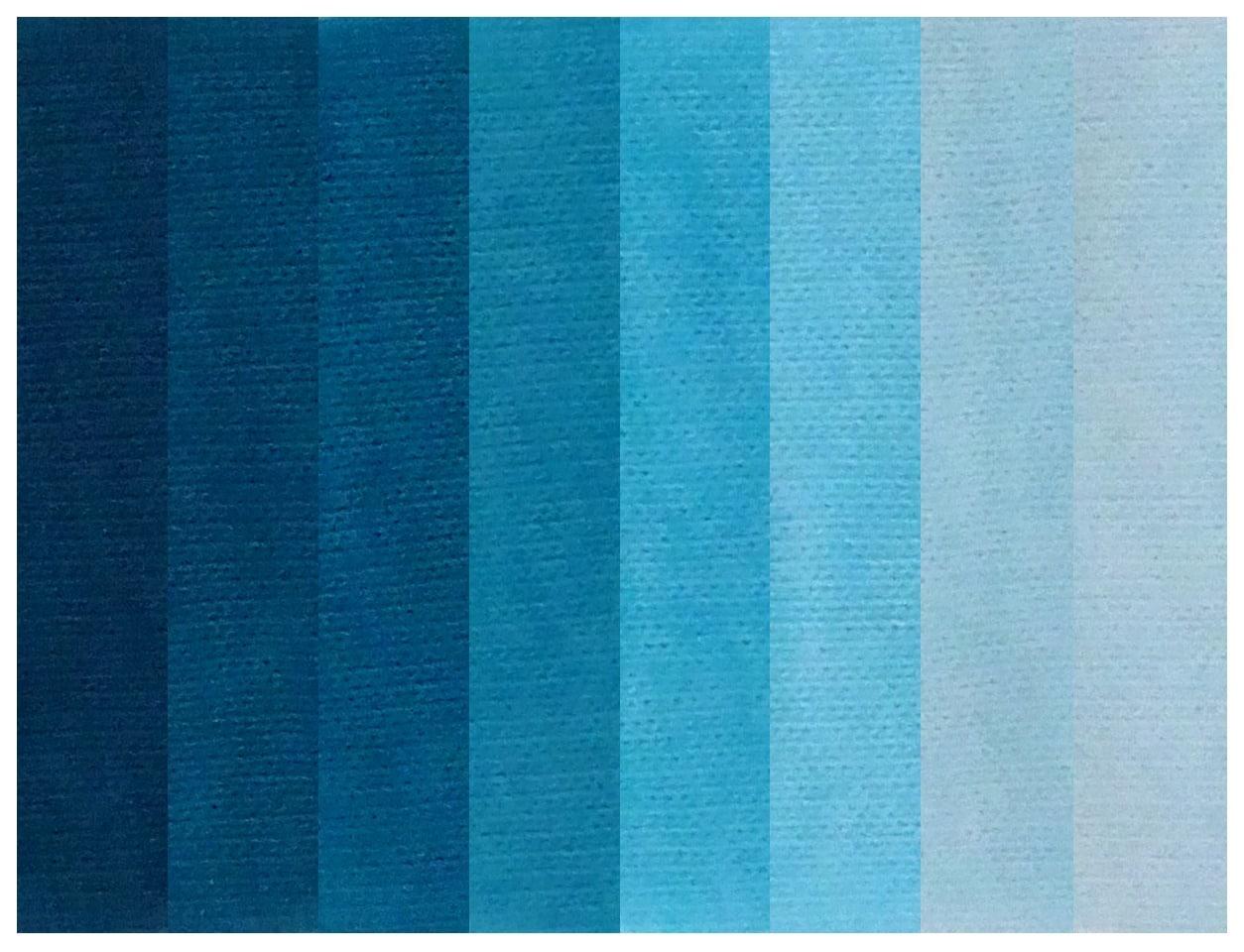

Getting to know PERMASET textile screen printing inks: Working with colour (Part 2)

Getting to know PERMASET textile screen printing inks: Working with colour (Part 2)

@imbueddesign

@imbueddesign

Getting to know PERMASET textile screen printing inks: Working with colour (Part 1)

Getting to know PERMASET textile screen printing inks: Working with colour (Part 1)

@home_work_

@home_work_

How to start screen printing at home

How to start screen printing at home

@blakdouglas

@blakdouglas

Hear how celebrated indigenous artist, Blak Douglas won the 2019 Kilgour Art Prize

Hear how celebrated indigenous artist, Blak Douglas won the 2019 Kilgour Art Prize

@imearthie

@imearthie

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand

Clothing label I’m Earthie shares how they strive to be a truly sustainable brand

@peopleofprint

@peopleofprint

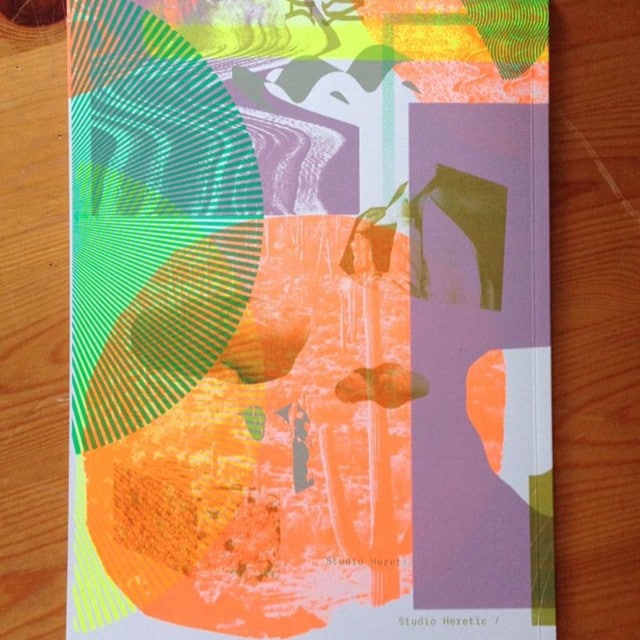

Hear how Heretic Printmakers UK printed magazines using PERMAPRINT Premium Inks

Hear how Heretic Printmakers UK printed magazines using PERMAPRINT Premium Inks

Hand printed block patterns

Read this helpful blog providing technical advice about how to block print using PERMASET Inks

Hand painted clothing

Learn practical tips and see examples of painting on fabric to create T-shirts, dresses, yardage, canvas artworks, bags and even shoes using PERMASET Inks

Meet the artists

This month we meet HEY REFLECT’O & see how PERMASET Ink has helped create their vision

Subscribe to get the latest inspiration, news & advice direct to your inbox

Learn how other printers are using water-based inks

@idressmyselfprint

@idressmyselfprint

Hear how I Dress Myself print shop has used water-based inks in their ethical business

Hear how I Dress Myself print shop has used water-based inks in their ethical business